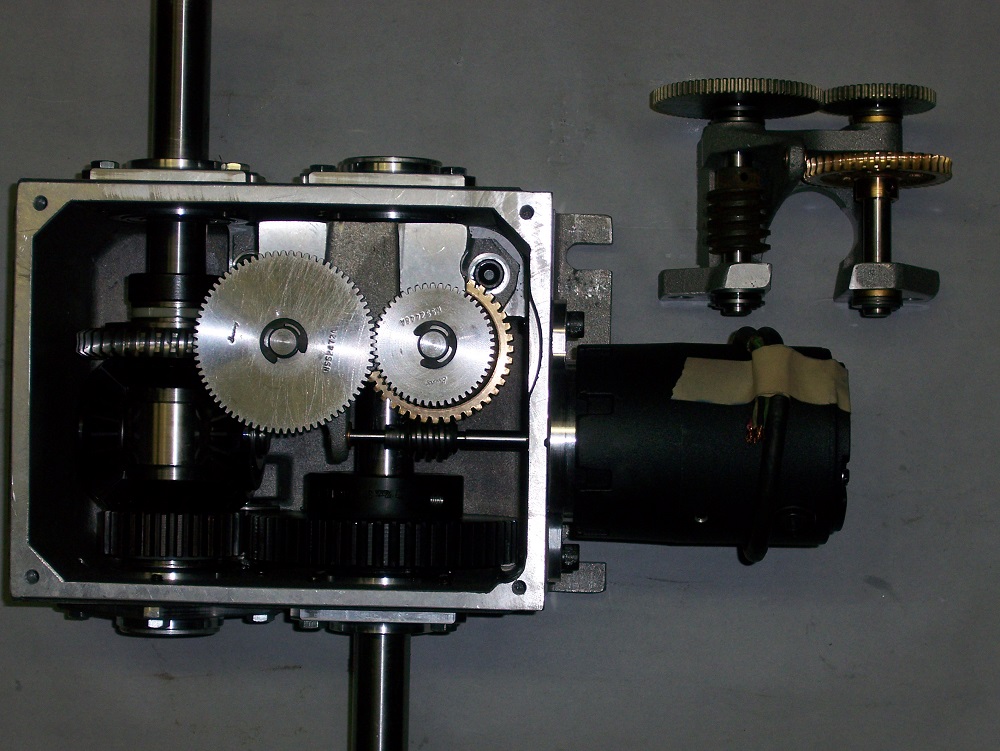

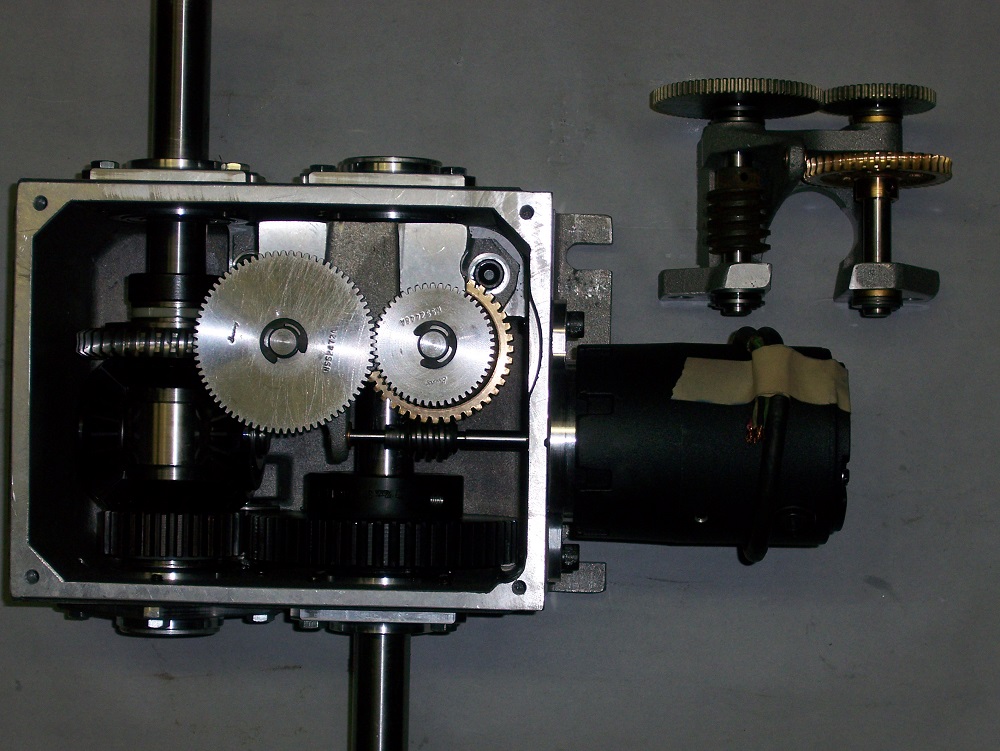

The T-2 Single Differential is use primarily on machinery with existing PIV length control units. This transmission will make the momentary phase corrections of the registration error.

The T-2 has a main shaft ratio of 1:1 with many different correction ratio options.

This 1:1 ratio is increases momentarily when an advance correction made, and decreases momentarily when a retard correction is made. The actual rate of the correction is determined by the internal ratio selected (see table 2) the time setting located on the front panel of the EMP Controller. The standard ratio supplied in most applications is 4800 turns of the correction motor will rotate the output shaft 360°. Using an EMP Controller with a time setting of 2 at 1.8° correction of the output shaft will taKe place.These momentary corrections will adjust the T-2's main output shaft's speed briefly increasing or decreasing the machine's draw roller speed and the amount of printed web delivered to the knife.replicas vacheron constantin

SEE DOWNLOADS TAB FOR ALL COMPONENTS & SPARE PARTS LISTING