|

|

|

|

It takes more than programming skill to successfully implement a Servo system. With EMP, you receive the full attention of experienced engineers who analyze all mechanical and electrical aspects of your machine to ensure a successful installation.

With the Series 1100, your operation will benefit from:

- Minimized Setup & Changeover Times - Customers report reducing setup times by as much as two hours!

- Automatically adjusts for changes in ratios in order to eliminate previously timely changeover procedures.

- Improved Efficiency - Practically eliminate wasted web.

- Improved Accuracy - Direct coupled servos improve overall precision.

- Increased Production - You tell us your desired speed and we design the system to meet it.

- Shaftless System Reduces Maintenance - Eliminate change gear stations, differential transmissions, positive infinite variable (PIV) gearboxes, clutch units, brake units, and other drive components that are the leading cause of machine downtime.

- Minimal maintenance and no oiling reduces your operating cost

- Increased Capability - With direct draw or knife roll mounted servo motors, your machine can handle any web length within your chosen range without the hassle of gears.

- Closed-Loop System - By delivering real-time feedback, the system can interpret data and issue precise corrections.

EMP offers quality custom-manufactured brackets for each Servo System based on your machine's dimensions. We do this to ensure accurate mountings and also to eliminate all belts and gears. We offer them at a reasonable extra cost to you because it ensures a proper installation in your plant.

orologi replica

With a Series 1100 Servo System, your operation will benefit from features such as:

- Custom EMP Software - Reduce the number of steps in setup and changeover procedures with software developed in conjunction with experienced operators.

- Show My PC to EMP Capability:

- Available on Windows XP touchscreens

- Save time and money by allowing for remote connection should EMP need to modify your system in anyway.

- Connection is made without "breaking" through your company's firewall; requiring no assistance from your IT department without compromising your network's security in anyway.

- Every EMP system is shipped with all the software it needs to run indefinitely with no annual software charges.

- Alarm Notifications - Multiple preprogrammed alarms not only recognize problems but also help determine particular component causing issues.

- Dual-Error Correction Ability - System is capable of precisely correcting both Random Phase Errors and Constant Length Errors.

- Sequence Setting - This feature is used to make the system follow the same pattern as the original print cylinder. It will allow your operation to run despite a poor quality printing job that results in a sequenced web.

- Diagnostic Software - Performs system check on components and alerts user of any issues.

relojes replicas

A Series 1100 System consists of the following components:

- Touch Screen - Adaptive user interface offers easy set-up and simple operation.

- Switching between products(labels, bags, etc) requires only entering the new desired cut length.

- Controller - Receives and analyzes feedback from Scanner, Encoder and Motor, and then issues precise correction to Servo Motor.

- Servo Motor - Brushless, DC motor provides position and velocity feedback signals to Controller, then receives correction signal and appropriately responds. All motors have MS Connector Termination and are rated IP65 for washdown environments.

- Gearhead - Provides necessary reducer ratio to system.

- Master Encoder - Provides machine speed and position of web. Mounted on a shaft with a 1:1 relationship to the machine.

- Scanner - Detects point of interest (registration mark, gap, splice, etc.) and supplies signal and location to Controller. The number of scanners can vary per application.

Our systems utilize as many standardized parts as possible. This approach to design allows us to easily service our systems and enables customers who stock repair parts to minimize their inventory costs.

The Applications Section of our website has images of various set-ups to help further your understanding of each component's role in various operations. The examples shown are some of our common installations but do not represent all of them.

|

Envelope & Cup Machine Operators Manual - Series 1100 Color T/S

Download File - 139.30 KB

|

|

Labeler Operators Manual - Series 1100 Color T/S [Non-Windows]

Download File - 150.04 KB

|

|

Labeler Operators Manual - Series 1100 Windows XP

Download File - 5.41 MB

|

|

Motor Tuning Manual - Series 1100 Color T/S

Download File - 5.94 MB

|

|

Operating the Counter (for specified customers)

Download File - 65.37 KB

|

|

Operators Manual - Series 1100 Servo w/ Keypad

Download File - 87.06 KB

|

|

Setting Up the Reset Feature (for specified customers)

Download File - 190.72 KB

|

|

Trine 6500/5500 PCB Schematic - Series 1100 Color T/S

Download File - 72.34 KB

|

|

Trine 6500/5500 Wiring Schematic - Series 1100 Color T/S

Download File - 51.25 KB

|

|

WD527 Schematic for Baldor BSM100C-6150AA

Download File - 786.13 KB

|

|

|

|

|

|

|

|

|

|

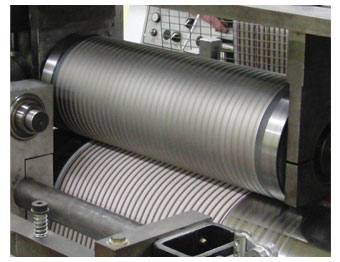

SERVO SYSTEMS CIGAR BAND DIE CUTTER |

|

|